to CEDS!

CEDS DURADRIVE GmbH - Drive systems from Salzbergen

Industries and their applications

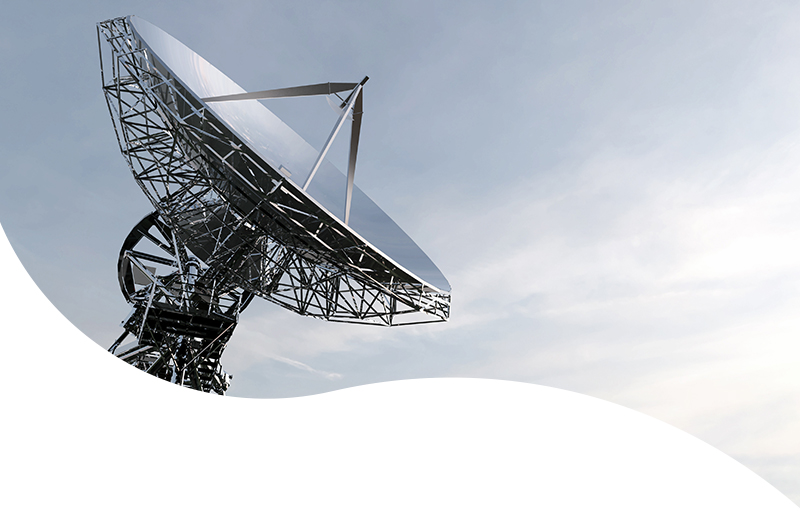

Different industries require different requirements of the respective drive technology. Safety, energy efficiency, efficiency, compact dimensions, high speeds or power development are some of the specifications that are placed on a drive. Drives with these special features must be individually designed and developed. With our know-how from 50 years of product and industry experience, we plan, design, develop and produce individual, specific customer solutions. We offer you the perfect drive for your industry and application.

They have very special requirements when it comes to the performance of a drive. And that’s a good thing. This means that we have precisely the individual standards that we use as the basis for the development and production of your very own drive. When it comes to safety, however, we set our very own standards. Because we are aware that our drives are a part, if not the heart, of the system for which you are responsible to your customer. We are happy to take on this responsibility. With drives that set standards in terms of durability and quality. So you can be sure that our drives always deliver what they promise.

As technologies advance, the demands placed on electric drive solutions also increase.

The wishes and requirements of our customers form the basis of our actions. We have been developing and producing durable and customized drive solutions for 50 years.

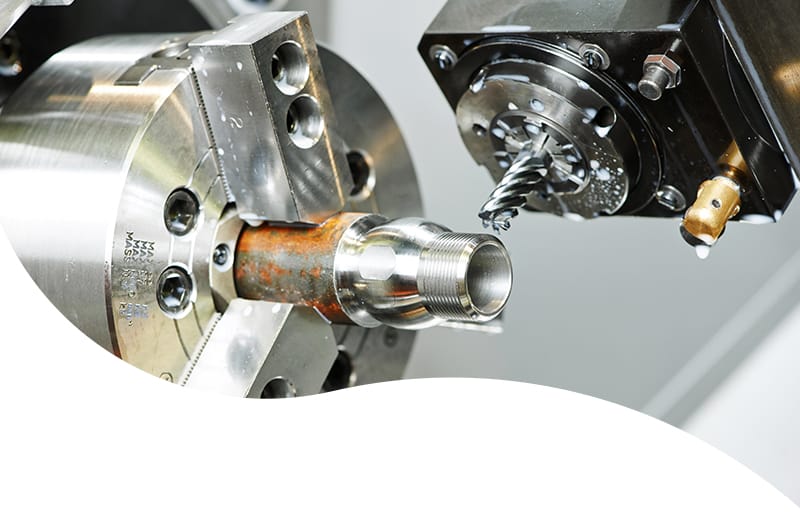

CEDS DURADRIVE has always combined design and production in one house, so the customer receives everything from a single source “Made in Germany. Made in Salzbergen”. Our vertical range of manufacture extends from machining to rotor assembly. This enables us to react quickly and flexibly to short-term requirements.

CEDS DURADRIVE is certified in accordance with the quality standards ISO 9001:2015 and DIN EN 9100:2018.

Motor technologies

As energy-saving as synchronous motors, synchronous servomotors offer further advantages in addition to adjustable speed: A high power density is just as important as a low mass moment of inertia and the possibility of very compact designs. All in all, this results in a motor for highly dynamic applications. Especially when a short cycle is required or accelerations are planned in the motion sequence. This is the case, for example, with drives for tool changers or axis drives in machine tool construction.