Core competencies

As technologies advance, the demands placed on electric drive solutions also increase.

The wishes and requirements of our customers form the basis of our actions. We have been developing and producing durable and customized drive solutions for 50 years.

CEDS DURADRIVE has always combined design and production in one company, so the customer receives everything from a single source “Made in Germany. Made in Salzbergen”. Our vertical range of manufacture extends from machining to rotor assembly. This enables us to react quickly and flexibly to short-term requirements.

CEDS DURADRIVE is certified in accordance with the quality standards ISO 9001:2015 and ISO 9100:2018.

Our core competencies at a glance

- CEDS DURADRIVE GmbH

- Neuenkirchener Straße 13

- D-48499 Salzbergen

Planning & construction

As a development partner and solution finder, we offer comprehensive application advice from our specialists even before the quotation phase. Each CEDS DURADRIVE drive is individually designed and constructed in close consultation with our customers.

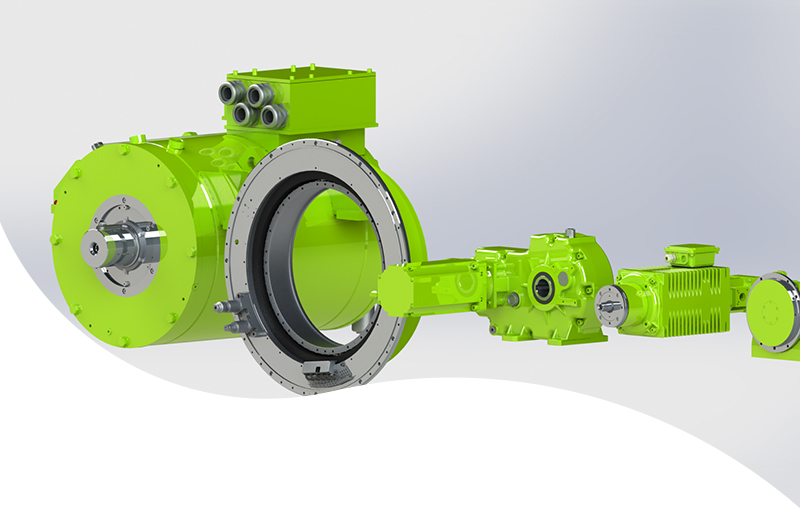

Form factors

When adapting the drive design to very special installation conditions, complex alignments and contours, special consideration must be given to the design. With our many years of expertise and our experienced production, we are the ideal partner for your requirements. Our special solutions for a wide range of industries illustrate this.

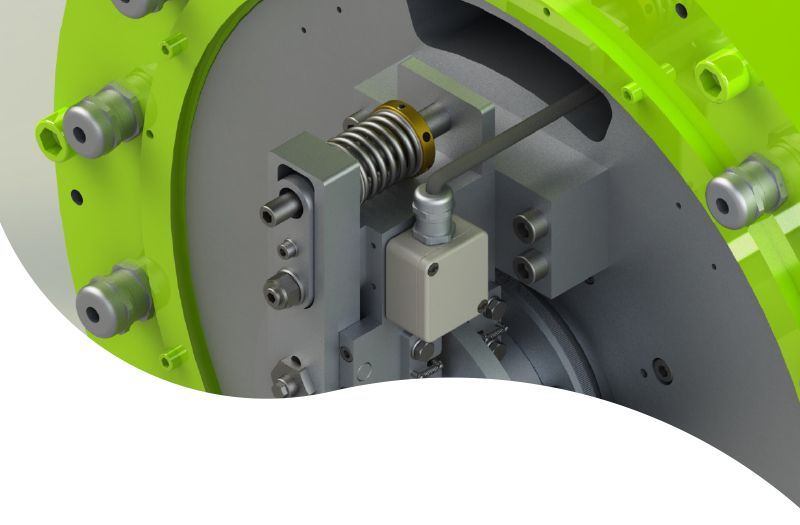

Mechanical connection

The very different adaptations to the various machine and system components require a high degree of variability in the rotary power transmission. Flange variations, mounting shapes and different contact points are among the mechanical requirements. An increased requirement, e.g. in terms of dynamics or performance, also means a greater load on the mechanical connection.

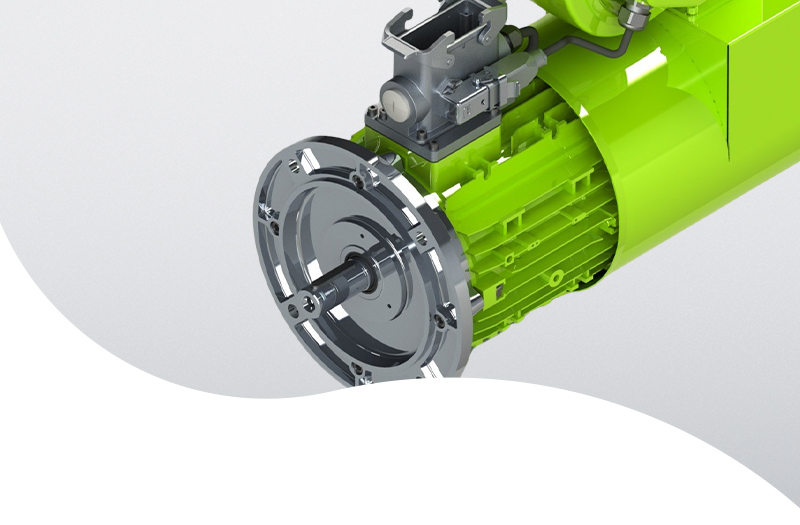

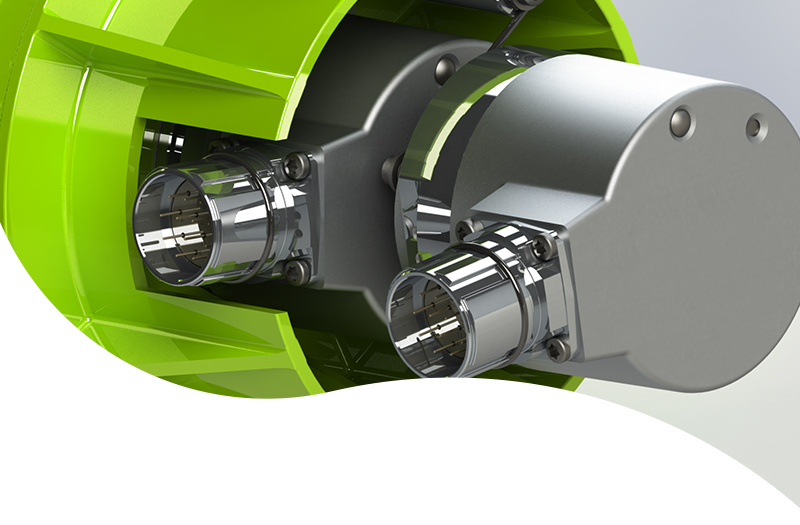

Electronic connection

Special environmental requirements and design characteristics often require a variable design of the electrical connection points. Here, environmental influences such as humidity, impermeability to dust and ease of servicing are decisive. Among other things, the performance values and shielding of the power cables and sensors must be taken into account.

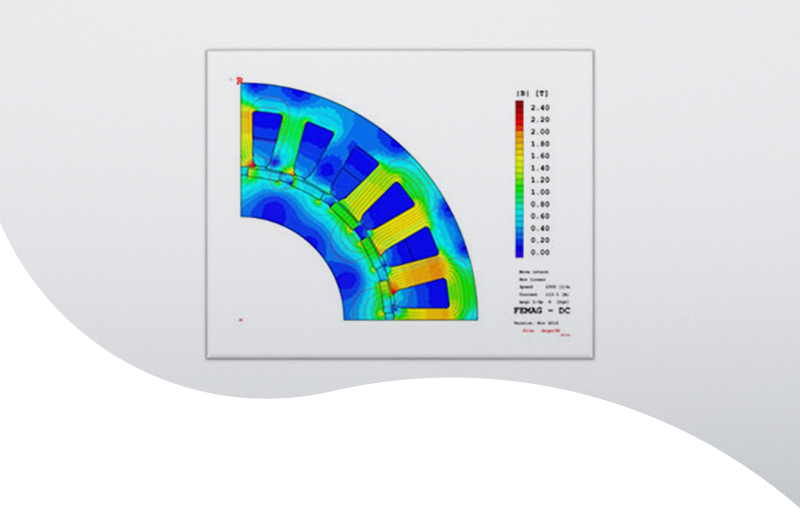

Motor design

To achieve the required performance data and drive performance, modern engineering tools are used to determine the magnetic circuit geometry, the thermal calculation and the strength and bearing service life calculation.

Cooling type

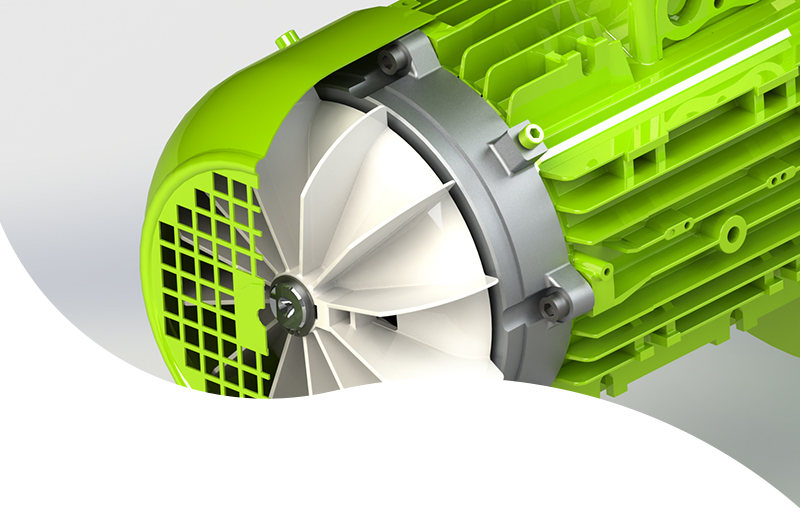

An effective, customized cooling option is essential for a high-performance electric drive that needs to achieve exceptional performance. Here we offer a comprehensive selection of cooling options. In addition to the standard cooling types, extended cooling types such as through-flow ventilation, water jacket or oil cooling are also possible. The optimum type of cooling and the optimum cooling system must be selected for the respective application.

Approvals

Drive solutions for locations with increased requirements in terms of special safety and hazards due to different environmental influences require corresponding approvals. “ATEX” for explosion protection or “Germanischer Lloyd” for shipbuilding are well-known examples. Together with our customers and the relevant authorities, we implement the necessary measures. CEDS DURADRIVE is certified to “ATEX” under PTB04 ATEX Q020-9.

Monitoring

Monitoring elements with different sensor technologies are used to detect malfunctions in good time and prevent damage. This optimizes maintenance intervals and control functions. Examples include speed, vibration and various temperature sensors.

Protection class

Adapted to the required and existing environmental conditions, the various standardized IP protection types are used.

Attachments

Various attachments such as encoders, brakes or forced cooling fans complement your specific drive solution.