Synchronous Motors

Synchronous Motors

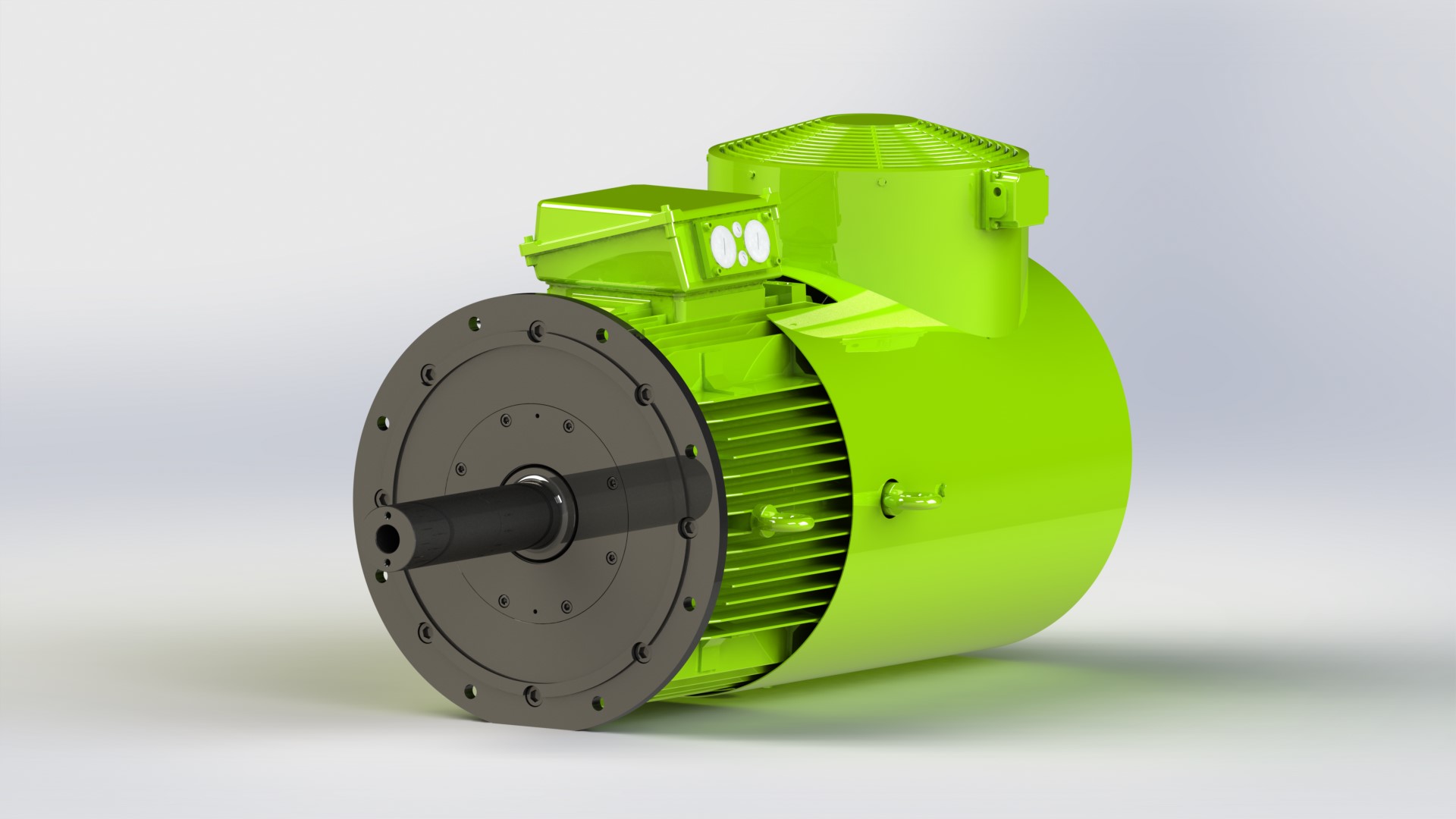

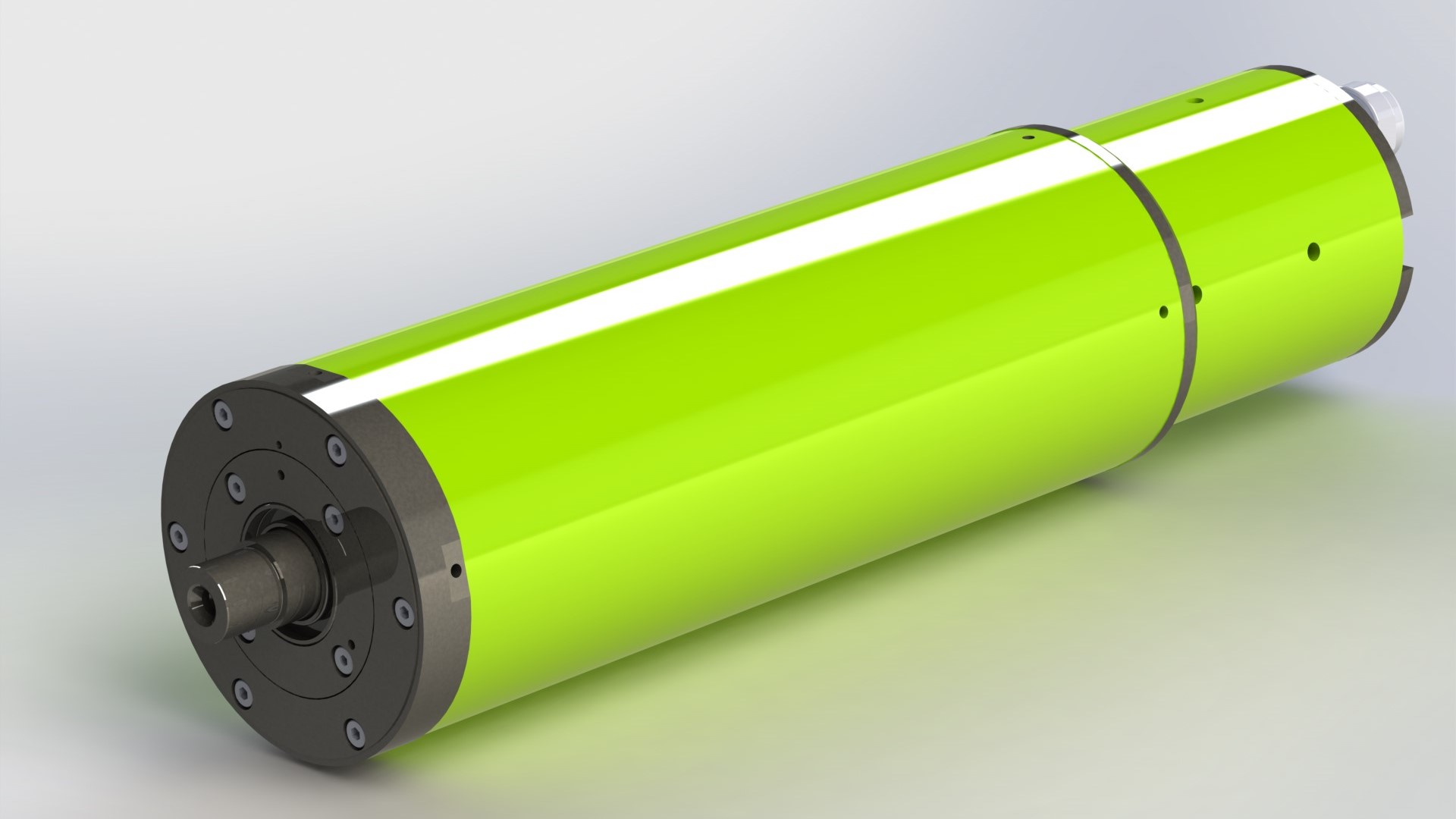

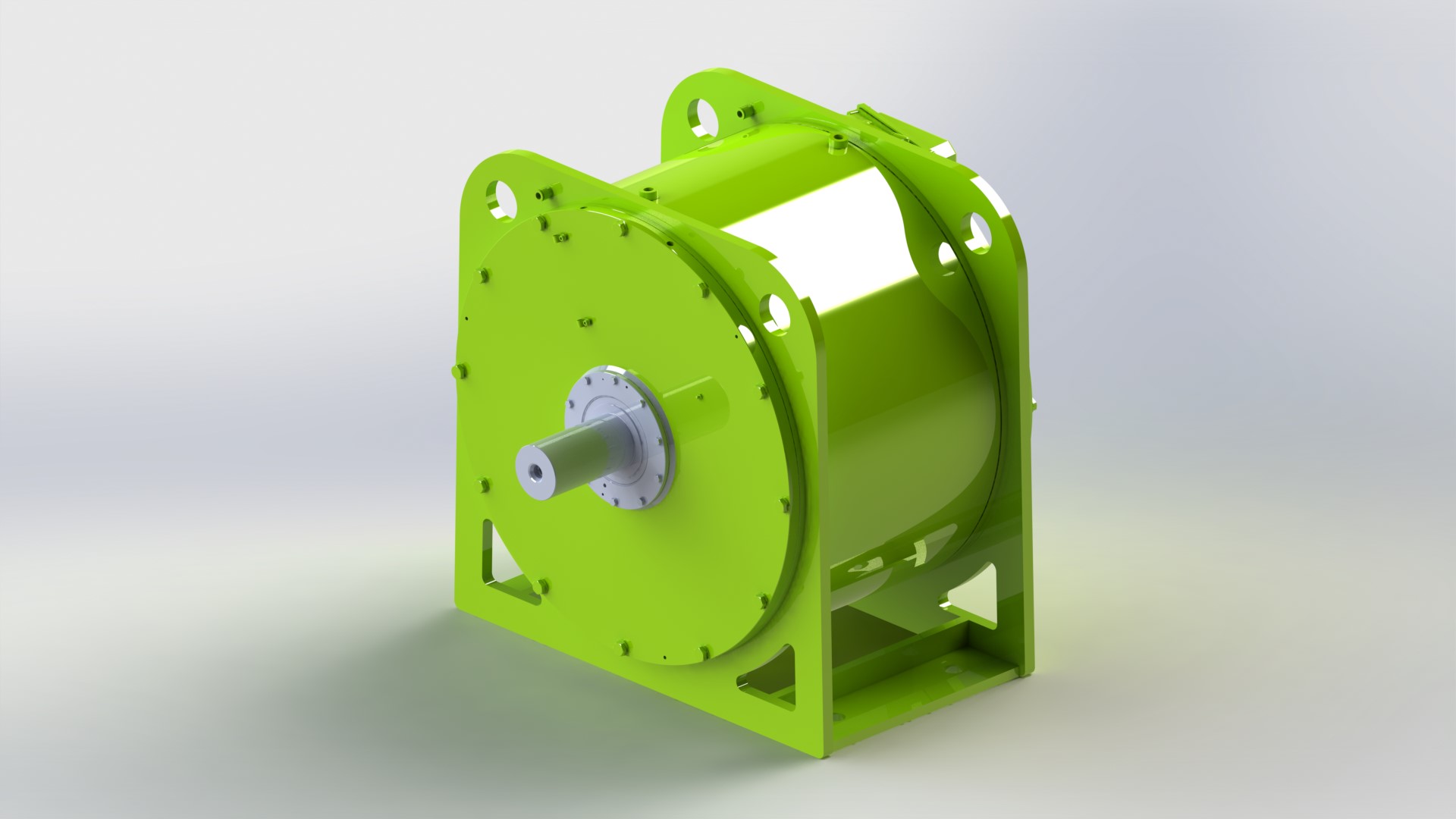

The synchronous motor essentially consists of a stator which, like the stator of an asynchronous machine, has a three-phase winding distributed symmetrically around its circumference and a rotating part separated by an air gap, the rotor.

Due to its geometrical arrangement and the supply of symmetrical alternating currents shifted electrically by 120°, the stator winding forms a rotating magnetic field in the air gap of the motor.

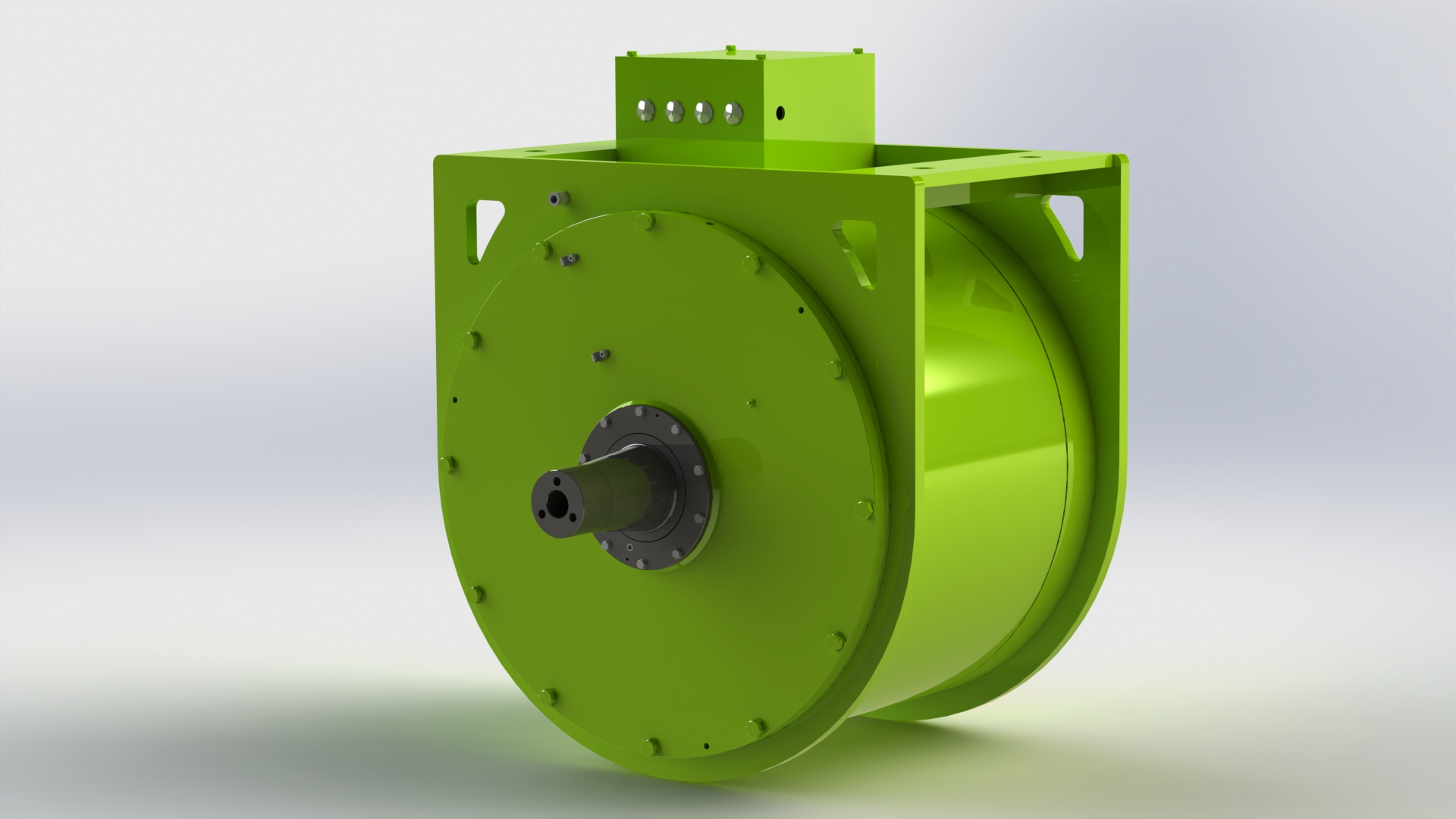

In most cases, the rotor of a synchronous machine is designed as a permanent magnet rotor and also has a damper cage to ensure smooth, stable running of the drive. Due to the interaction of the two magnetic fields of stator and rotor, rotary motion occurs.

Since the rotor is designed as a permanent magnet rotor, the operating behaviour of the synchronous motor is more dynamic than that of the asynchronous machine. A synchronous motor has a significantly lower rotor inertia than an asynchronous machine due to its higher efficiency at the same power output. A further advantage of the synchronous motor is that, due to the stationary magnetic field of the rotor, it maintains its speed independent of an external load up to a limit value, the outrunning torque, and the drive can be operated with frequency control without additional cost-intensive encoder systems such as resolvers or incremental or absolute value encoders. Synchronous motors can be operated with variable speed at the inverter or with fixed speed proportional to the mains frequency, directly at the mains.

The CEDS DURADRIVE synchronous motors can be built with a wide variety of cooling concepts, such as self-cooling, self- or forced cooling. In addition, water jacket cooling is also possible for particularly compact designs. They can be implemented as both internal and external rotors for your application.

If required, CEDS DURADRIVE synchronous motors are mechanically and electrically individually adapted to the special requirements and also to the specifications of our customers with regard to environmental influences and legal requirements. Therefore, high requirements regarding the protection class up to IP 6K8K, extremely high requirements regarding surface protection or certifications according to ATEX, DNV GL or Bureau Veritas are not uncommon for us.

CEDS synchronous motors offer you special features, which are as follows:

- Very high acceleration capacity

- Light and compact size

- Efficient, related to size

- High efficiency even at low rotation speed

- High speed stability

- Very high rotation speed can be realized

- Reinforced winding insulation for high dielectric strength and thus better resistance to partial discharge within the winding

- Quiet movement

- Low reactive power requirement

- Synchronous running of several drives even with different loads

Fields of application

- Machine Tools

- Use with very limited installation space

- Compressor / Extruder

- Wind Energy

- Hydropower

Technical parameters

| Parameters | Synchronous Motors |

|---|---|

| Size | IEC standard or larger according to Transnorm |

| Power (P) | 100 W to 1 MW |

| Turning moment | 1 Nm - 10 kNm |

| Voltage range | to 690 VAC |

| Efficiency | up to 97 % |

| Power density | high (very compact drives possible) |

| Magnets | NdFeB or SmCo |

Precise configuration for your application

CEDS DURADRIVE GMBH

Neuenkirchener Straße 13

D-48499 Salzbergen

+49 5976 6449 0

+49 5976 6449 113

vertrieb@ceds-duradrive.de

- CEDS DURADRIVE GmbH

- Neuenkirchener Straße 13

- D-48499 Salzbergen

- +49 5976 6449 0

- +49 5976 6449 113

- vertrieb@ceds-duradrive.de