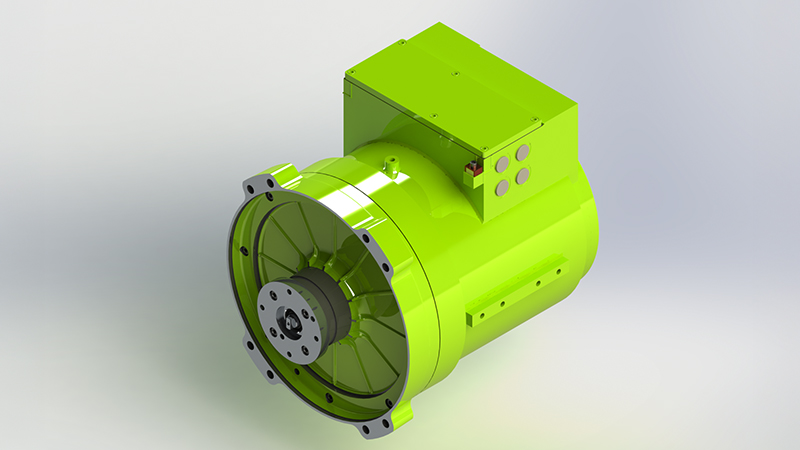

Asynchronous motors

The most commonly used three-phase motor is the asynchronous motor. The reasons for this lie primarily in its simple and robust design, as well as its high operational reliability and extremely low maintenance and care requirements. Due to its overall simple design, the asynchronous motor can also be manufactured cost-effectively and is therefore particularly suitable for large quantities.

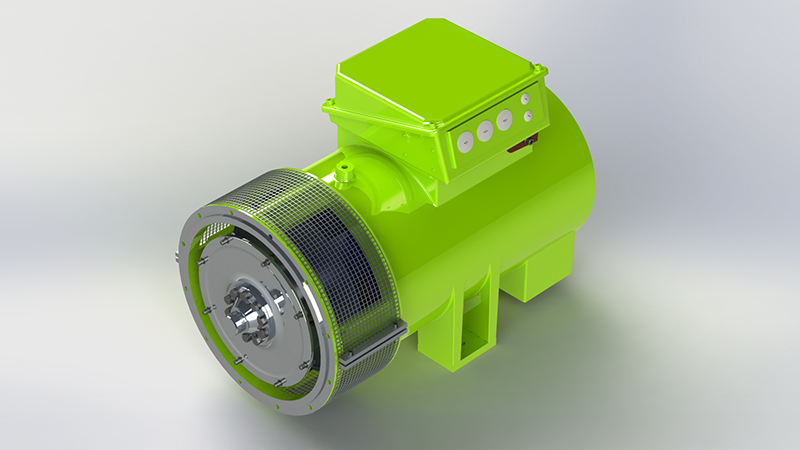

The asynchronous motor essentially consists of a stator and a rotating part, the rotor, which is separated by an air gap. The stator usually has a symmetrically distributed, three-strand winding, which is embedded in a soft magnetic, axially laminated stator core. Alternating currents flow through the winding of an asynchronous motor at an angle of 120° to each other. This results in the formation of a rotating circular field, which has an inductive effect on the rotor.

Due to today’s widespread and cost-effective frequency inverter technology, the rotor is almost exclusively a permanently short-circuited squirrel cage rotor, also known as a squirrel cage rotor. Slip ring rotor versions for torque adjustment are only very rarely found on the market. They are significantly more expensive and also subject to wear and require more maintenance. The cage material is an aluminum alloy that is mechanically inserted into the axially laminated rotor package, which is also soft magnetic and equipped with grooves. Due to its approximately 1.7 times higher conductivity, the use of copper as a cage material makes it possible to significantly reduce the current heat losses in the rotor and thus build more efficient, possibly smaller asynchronous motors with lower current requirements. Today, copper rotors can only be produced by machine up to a limited size and are more expensive than die-cast aluminum rotors.

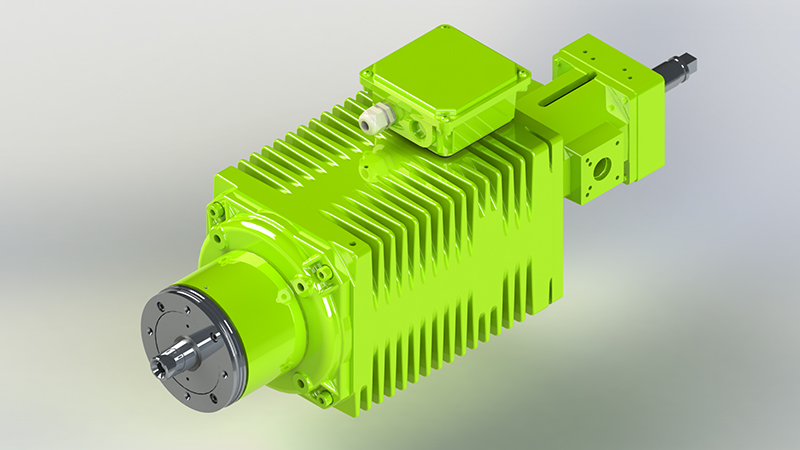

Another important aspect to consider when selecting a suitable asynchronous motor as a drive concept is its heat dissipation. With liquid-cooled asynchronous motors from CEDS DURADRIVE, drives with an increased power density can be realized compared to conventionally cooled motors. The required installation volume and possibly also the total weight of a liquid-cooled motor are significantly lower than that of a surface-cooled machine with identical torque at the same speed. The pull-through ventilation variant represents a further increase in the generation of higher continuous torques.

Asynchronous motors that can be heavily overloaded for short periods can be designed using a sheet metal geometry that is individually tailored and adapted to the application. They generate a peak torque of up to four times the nominal torque.

CEDS DURADRIVE asynchronous motors can be mechanically and electrically customized to meet specific requirements and can also be adapted to our customers’ specifications with regard to environmental influences and legal requirements.

Therefore, high requirements regarding the protection class up to IP 6K8K, extremely high requirements for surface protection or certifications according to ATEX, DNV GL or Bureau Veritas are not uncommon for us.

CEDS asynchronous motors offer you special features

- Low maintenance

- Long service life

- Compact designs

- Special designs

- High overload capacity due to high tilting moment

- Large field weakening range with constant power

- Overload protection through temperature sensor in the winding or on the bearing

- Reinforced winding insulation for high dielectric strength and thus better resistance to partial discharge within the winding

- Low-noise design

- High speeds can be achieved

- Controllable with position encoder and frequency inverter

- Volt-free rotor and can therefore run in liquids, gases and in a vacuum

- Favorable manufacturing costs

Areas of application for asynchronous motors

- Conveyor technology

- Fans and air conditioning

- Compressors and compressors

- Pumps

- Mixers and kneading machines

- Lifting technology

- Construction machinery

- Machine tools

- Rail vehicles

- Travel drives

- Rollers

- Hybrid drives

- Centrifuges

- Grinder drives

Technical parameters for asynchronous motors

| Parameters | Asynchronous motors |

|---|---|

| Size | IEC standard or greater according to Transnorm |

| Power (P) | up to 600 kW |

| Torque | 1 to 5,000 Nm |

| Speed | up to 30,000 rpm. |

| Voltage range | up to 690 VAC |

| Efficiency | up to 96 % |

| Power density | medium |

- CEDS DURADRIVE GmbH

- Neuenkirchener Straße 13

- D-48499 Salzbergen

When you choose a drive from CEDS DURADRIVE, you get a “tailor-made suit” – in other words, a solution that is perfectly designed and tailored to your needs.