Direct current motors

Since its foundation in 1970 as SSB Elektromaschinen GmbH & Co KG and its later expansion as SSB Antriebstechnik, CEDS DURADRIVE has also been producing DC motors. Almost half a century later, CEDS can proudly look back on a wealth of experience in the design and manufacture of DC motors in this sector.

The DC motor consists of a stator and a rotating part, the armature, which is separated by an air gap. The armature is wound with coils that are connected to a commutator. The polarity of the armature winding is changed during rotation via the sliding contacts (carbon brushes), which run on the commutator, thereby generating a constant torque.

Pitch systems in wind turbines are a large area in which DC motors are still used. Due to their design, DC motors in pitch systems can be moved and turned to a safe flag position in the event of a power failure by means of direct control by a battery.

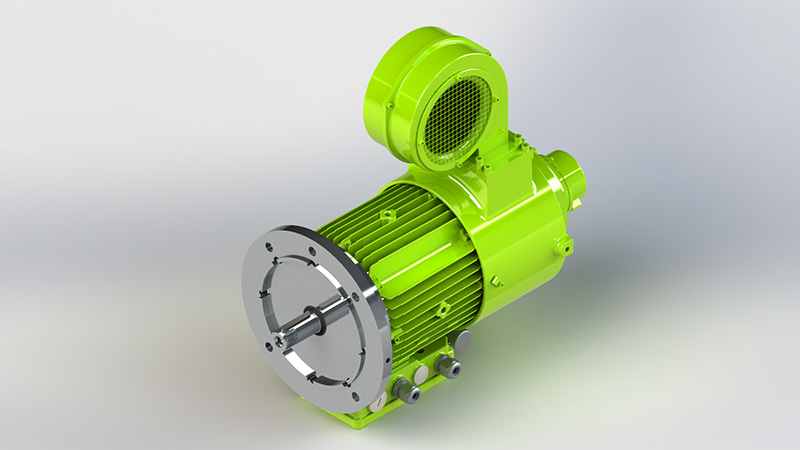

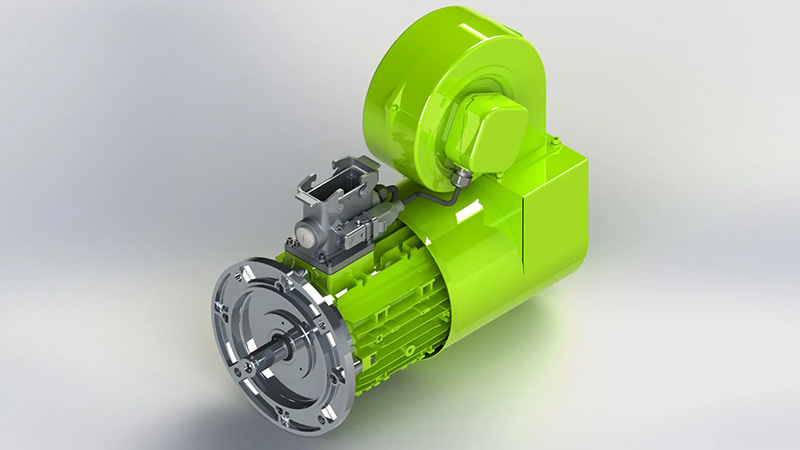

Servo technology can be integrated into DC machines when using DC motors that require relatively high positioning accuracy. The additional module required for this is an encoder system, which can take the form of a resolver, incremental encoder or often an absolute encoder. This allows the exact speed of the motor to be read out and the exact position of the armature to be determined. In controlled operation, this can be used to achieve synchronization of several drives, for example, or to achieve good positioning.

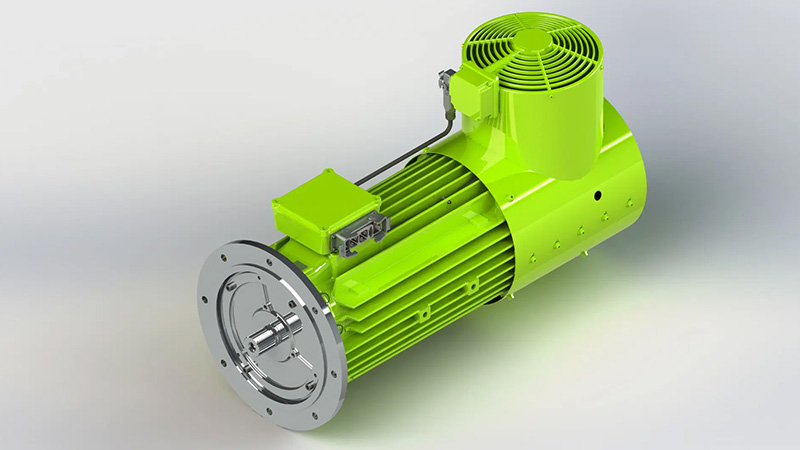

CEDS DURADRIVE DC drives are electrically and mechanically customized solutions that comply with customer specifications as well as legal requirements and are adapted to the climatic operating conditions. High degrees of protection or durable surface protection against harsh environmental conditions are not uncommon for us.

CEDS DC motors offer you special features

- Very wide speed control range, additionally extendable by field weakening range

- Standstill load capacity with rated torque

- Short rise times due to small armature circuit inductance

- Very high current change speed

- High overload capacity

- Cycle operation with multiple rated torque for acceleration possible, without influence on brush service life

- Direct battery emergency drive in the event of a power failure

- High starting torque

Areas of application for DC motors

- Wind turbines

- Positioning

- Synchronization systems

- Winding tasks

Technical parameters for DC motors

| Parameters | Direct current motors |

|---|---|

| Size | IEC standard or greater according to Transnorm |

| Power (P) | 100 W to 30 kW |

| Speed | according to requirement |

| Torque | according to requirement |

| Voltage range | up to 560 VDC |

| Efficiency | according to requirement |

- CEDS DURADRIVE GmbH

- Neuenkirchener Straße 13

- D-48499 Salzbergen

When you choose a drive from CEDS DURADRIVE, you get a “tailor-made suit” – in other words, a solution that is perfectly designed and tailored to your needs.